The turbomachinery operating within a refinery hydroprocessing unit requires some of the most capable actuation in the world. These compressors and pumps must be controlled accurately and reliably for a refinery to meet its operational goals. Typically, this machinery is driven by a steam turbine which converts thermal energy to rotational energy. A poor controlling or unreliable actuator can lead to inefficiency which erodes the bottom line and/or unplanned shutdowns which interrupt throughput. The inlet steam control actuator is arguably one of the most critical and valuable components within a hydroprocessing unit.

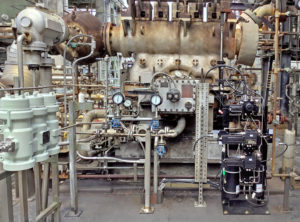

REXA recently upgraded a series of steam turbines driving hydrogen recycle compressors at a refinery in Mississippi. These steam turbines were operated by OEM style hydraulic actuators utilizing pilot valves and power pistons requiring an external oil supply. External oil supply circuits are common in many older OEM actuator systems but come with significant drawbacks. The biggest being oil contamination and a need for frequent and costly maintenance. In addition, the internal varnishing within the system can cause static friction (stiction) resulting in poor control. The original actuator exhibited a position hunting effect which ultimately led to poor control of the steam turbine with large RPM swings –disrupting the downstream process.

Refinery personnel consulted REXA’s industrial rotating equipment specialists, who developed a user-specific solution. After reviewing the issues, REXA proposed its Rotating Equipment Total Integrated Solution. This specialized package includes an on-site evaluation and training, custom engineered actuator mounting hardware, 3D installation drawings, TAR supervision and support, and actuator integration/calibration.

REXA’s self-contained design eliminated the need for an external oil supply. Each part of the REXA hydraulic circuit is positive pressure and never meets atmospheric contaminants – eliminating the need for filtration or routine oil changes. By utilizing REXA’s self-contained design for their steam turbine speed control, the customer was able to achieve tighter RPM control and even full automatic startup without operator intervention. Unplanned shutdown/nuisance trips have also been eliminated.

Before

After

Download the full success story & learn more

Click the button below to download the full success story! Interested in learning more about our solution for other applications? Click here to further explore REXA in other applications.