Compressor Anti-Surge Control

Background

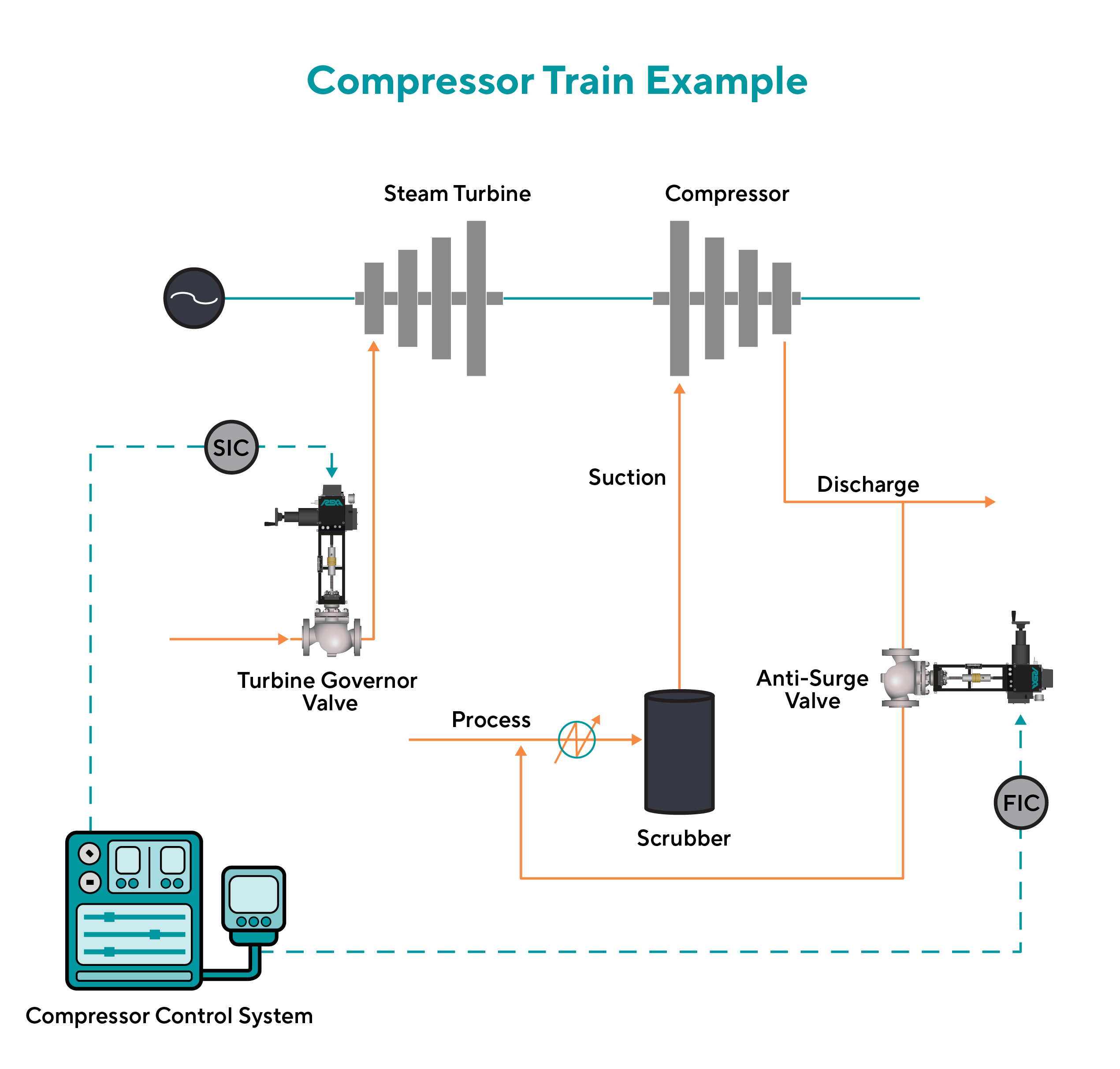

Axial and centrifugal compressors are expensive, critical pieces of equipment that are found at the heart of many industrial processes and across a multitude of industry segments. Implementing the correct, high performance compressor control strategy has direct impact upon the control of the process and the profitability of the plant. It is important to have control that is both responsive and stable to improve yield and ensure compressor availability is maximized. One of the main applications to ensure maximizing availability and throughput is Compressor Anti-Surge Control. Process dynamics that are common during start-up and shutdown sequences, as well as when a compressor is operated at a reduced throughput, can cause compressor surge events. The surge phenomenon is created when a flow reversal through the compressor occurs due to it’s inability to overcome the pressure stored in the discharge volume. An Anti-Surge Valve (ASV) is utilized to protect the compressor by safely recycling gas from the discharge side to the suction side in order to keep the compressor operating point safely away from the surge limit.

The Anti-Surge Valve requires an actuator capable of immediate response to signal change (minimal deadtime), rapid stroking speed, and precise modulating control. In a surge scenario, the ASV is designed to rapidly open in order to protect the compressor, typically under 2 seconds, and occasionally as fast as 500msec. This action moves the operating point away from the surge limit line and allows the compressor to resume normal operation. Accurate and precise control, with minimal deadtime for steps of all sizes, is critical to keep the compressor out of surge in the first place, but equally as important in stabilizing this extremely fast process. Valve positioning hysteresis and overshoot can create and accelerate upset conditions within the process.

Problem

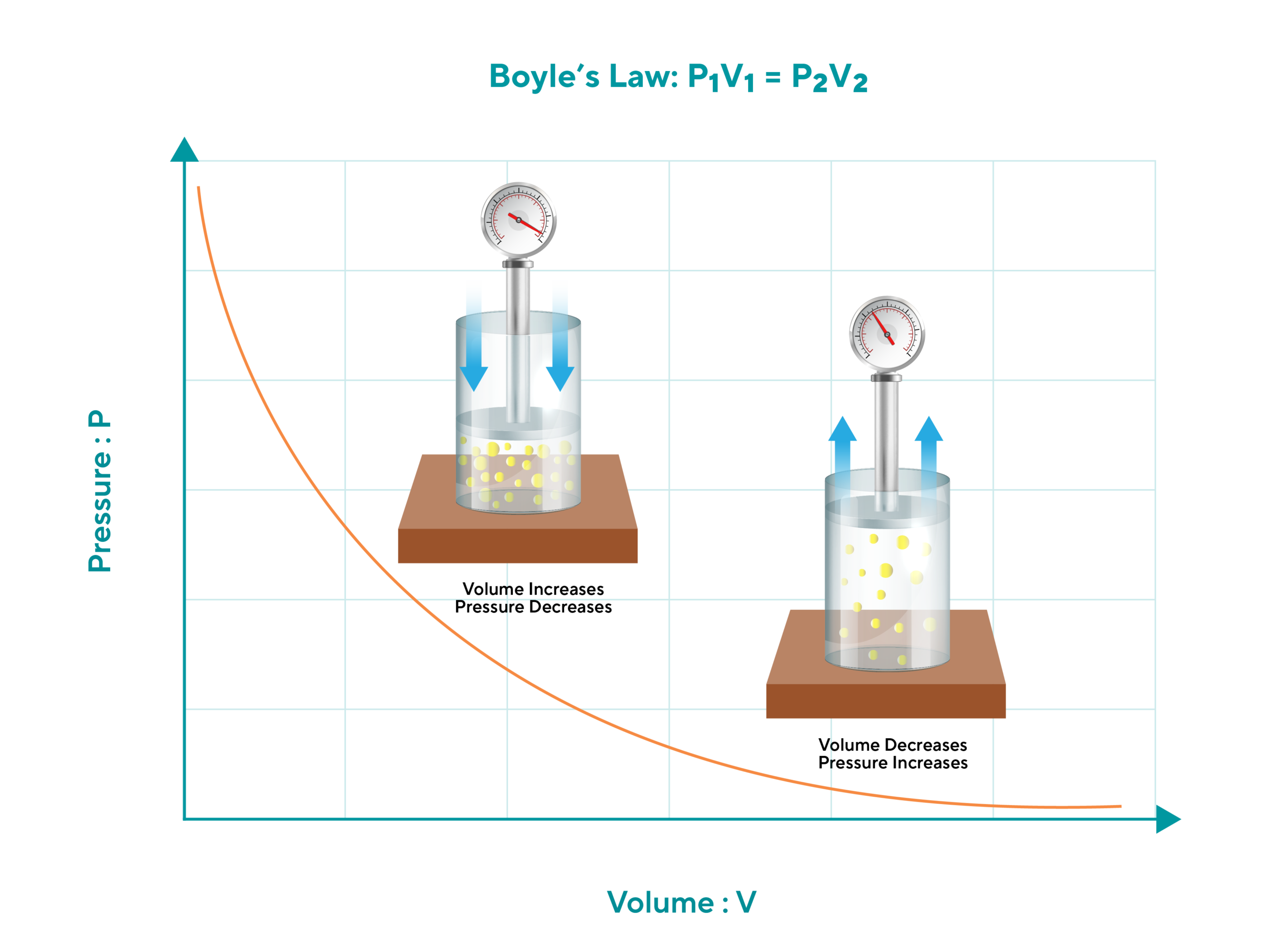

Anti-Surge Control Valve suppliers offer actuation packages as part of the valve assembly. These valve assembly packages are commonly offered with the supplier’s brand of pneumatic positioner (smart or traditional). Great efforts have been made to engineer the specifications of the application to meet the best performance that can be achieved with pneumatic actuation. What is constant across all pneumatic actuation is the effect of Boyle’s Law. Boyle’s Law explains the inverse relationship of pressure and volume with respect to a fixed amount of gas. This relationship states that P₁V₁ = P₂V₂. This principle explains the effect of jump and overshoot (hysteresis) inherent to all pneumatic actuation. Every time a pneumatically operated valve is required to move it needs to overcome the force of static friction (P₁)(area) to initiate movement. Once it overcomes static friction the dynamic friction force is greatly reduced (P₂)(area). Plugging into a Boyle’s Law formula, the drastic reduction in pressure requires a drastic increase in volume to equalize the equation. That increase in volume is directly translated to overshoot in a pneumatic system. The goal of a smart positioner, regardless of the manufacturer, is to limit the amount of jump/overshoot as pneumatic response can be predicted. The trade off with “controlling” this effect is a greatly slowed response, which is artificially adding deadtime into the loop. On small step changes (less than 0.5%) the impact can be many seconds, in some cases greater than 10 seconds. In this application where the impact on compressor efficiency and throughput can be so easily affected by process disturbances, pneumatic actuation on compressor control can have a refinery FCC cost of downtime over $1,500,000 per day in gasoline production alone.

Solution

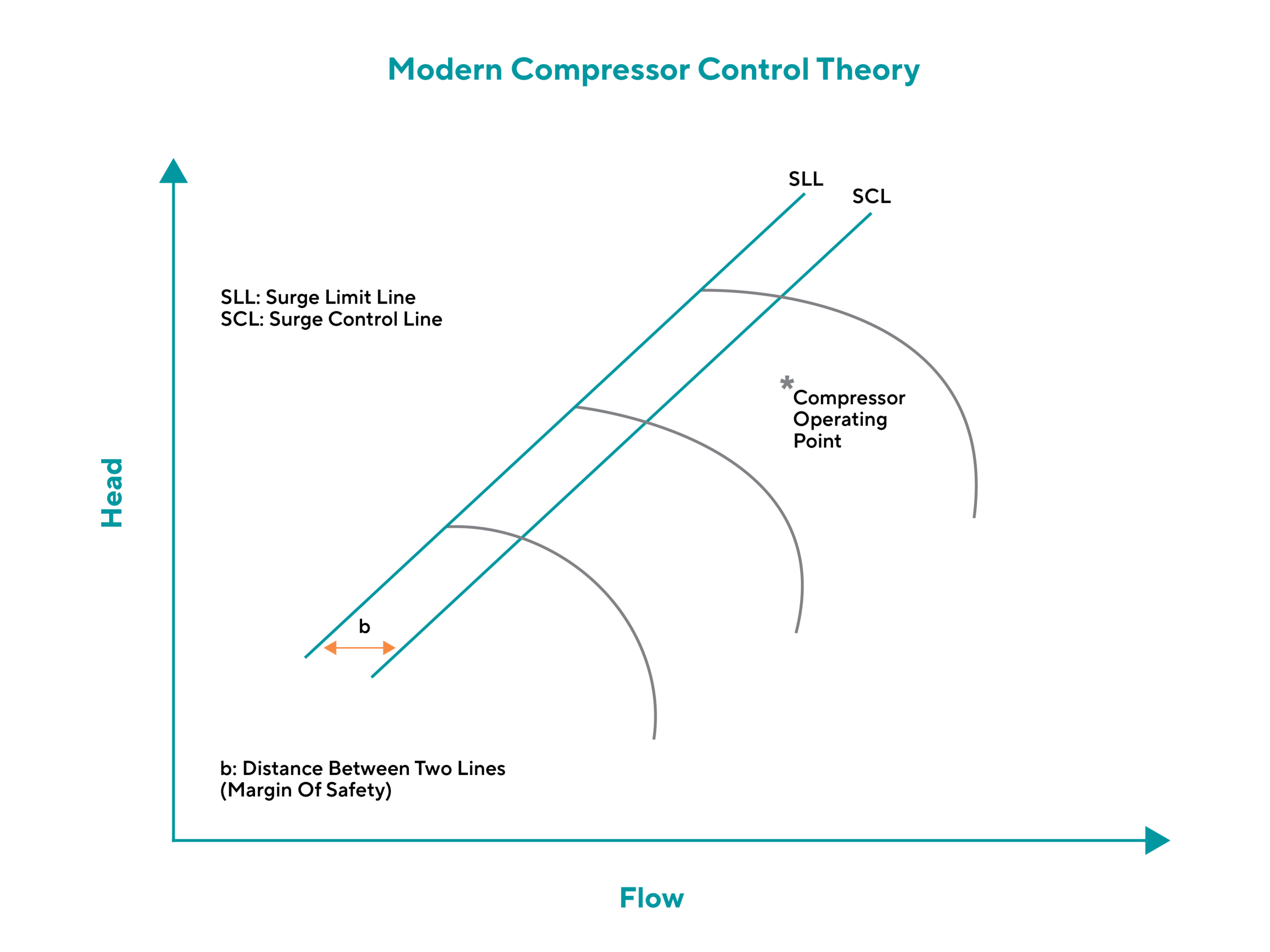

In modern compressor control theory, a Surge Control Line (SCL) is developed to protect the compressor, so a required safety margin is necessary to prevent approaching the Surge Limit Line (SLL). See the graph below. The SLL is the minimal flow point before the compressor becomes highly unstable. Crossing above the SLL causes the compressor to enter a surge condition. The SCL is typically established at around a 10% flow margin of safety to the right of the SLL but is dependent upon both the process dynamics of the system surrounding the compressor, and system’s response at different loads (ASV speed of response). The performance of critical valves, like the ASV, is a significant determining factor on loop performance. Some processes require a large margin of safety between the SCL and SLL to prevent the compressor from going into frequent surge cycles. As the required margin of safety increases, the envelope of the compressor map decreases in size resulting in lower operational efficiency of the compressor. A less efficient compressor is not desirable but is better than a compressor that is frequently in surge. There are two critical requirements of an ASV that the Anti-Surge Control application needs to meet to ensure the compressor control is optimized. The first requirement is to open the ASV in a stable and precise manner. The compressor controller uses suction pressure, discharge pressure, flow, and temperature inputs while utilizing Proportional Integral Derivative (PID) controller close loop response to cope with typical process changes. The ASV receives command from the controller and begins to open before the unit reaches a surge condition. Minimal deadtime, precise control, and minimal overshoot from the ASV are critical to loop performance, particularly on small operating point changes. The second requirement of the ASV is to be able to open rapidly when a rapid surge approach does occur due to a major process upset.

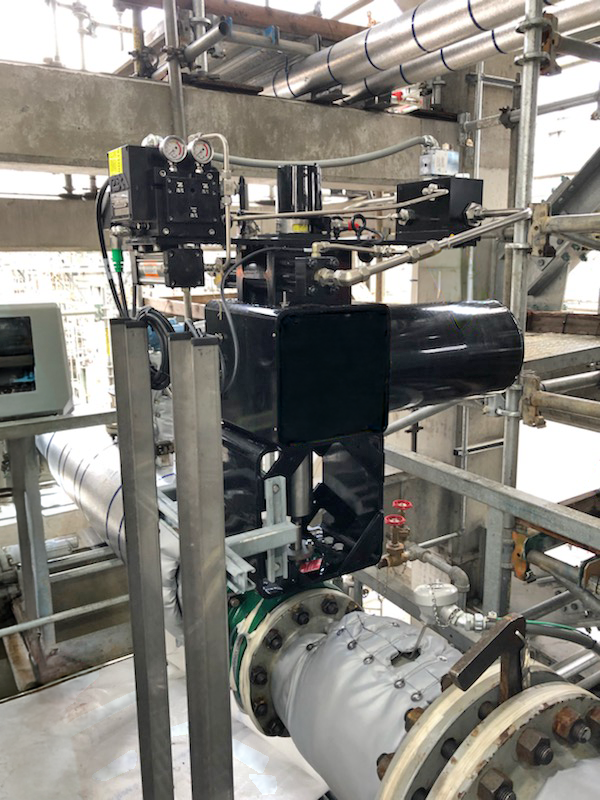

To meet the critical requirements of Compressor Control, REXA actuators, based on the company’s proprietary Electraulic™ Technology, are the perfect choice. The self-contained actuators combine the simplicity of electric operation, the power of hydraulics, the reliability of solid state electronics, and the flexibility of user-configured control. Electraulic™ Technology is comprised of an actuator assembly and electrical control enclosure. The principle behind its technology is a unique hydraulic circuitry called the Flow Match Valve (FMV) system. The actuator incorporates a bi-directional gear pump coupled to either a stepper or a servo motor that provides a highly-efficient method of pumping hydraulic fluid from one side of a double-acting cylinder to the other. The discrete operation of the motor and pump creates action only when a position change is required. Once the required position is reached, the motor shuts off and the FMV system hydraulically locks the actuator in place. Minimal power is required to maintain actuator position. The motor and pump sit idle until a new command signal is received.

Results

REXA Electraulic™ Actuators easily meet and exceed the critical requirements for stable compressor control.

•Hydraulically driven (non-compressible)

•Tighter positioning control compared to pneumatic actuation

•Precisely positioned down to 0.05% of stroke

•Minimal deadtime (50-70msec)

•500msec full stroke trip

•Moving the compressor operating point away from the SCL

The result of utilizing REXA Electraulic™ Actuation is improved performance of the entire compressor train. This enables the plant to get better return out of their compressor control system. Accurate and precise ASV actuation allows for a large reduction, and in some cases, elimination of surge events. Eliminating surge events means less time in recycle, increased throughput, and fewer process interruptions due to plant upsets or compressor trips. Reduced deadtime and more precise control allow for improvements in the compressor’s performance. With Anti-Surge Valves no longer subject to hysteresis, the compressor map can be expanded, and higher compression ratios can be achieved. Higher compression ratios and compressor speeds directly lead to an increase in production. In a typical refinery, ammonia plant, ethylene plant, or similar facility, enhanced actuator positioning can significantly cut recycled gas resulting in lower steam usage (approximately 7,500 lbs/hr) and potential annual savings of around $250,000. This improvement also allows operation closer to the surge limit while maintaining stability, by ensuring minimum gas flow through the compressor and avoiding overpressure conditions. Contact REXA to learn how we can help optimize your plant’s performance!

Literature

Download the full Compressor Anti-Surge Control Application Spotlight!