XPAC Series 3 Actuators and Drives

The REXA XPAC Series 3 Electraulic™ Actuator is a superior positioning device well suited for critical control applications. XPAC Series 3 is designed to control critical processes in harsh environments while providing long-term reliability. REXA actuators and drives provide the final control element capabilities to match the most sophisticated instrumentation and distributed control systems. Savings from reduced maintenance, lower energy consumption, minimized labor costs, improved quality, and avoidance of unplanned downtime add up quickly. REXA actuators consistently demonstrate high return on investment (ROI) across a variety of industries achieving fast payback periods and delivering substantial value well beyond the initial investment.

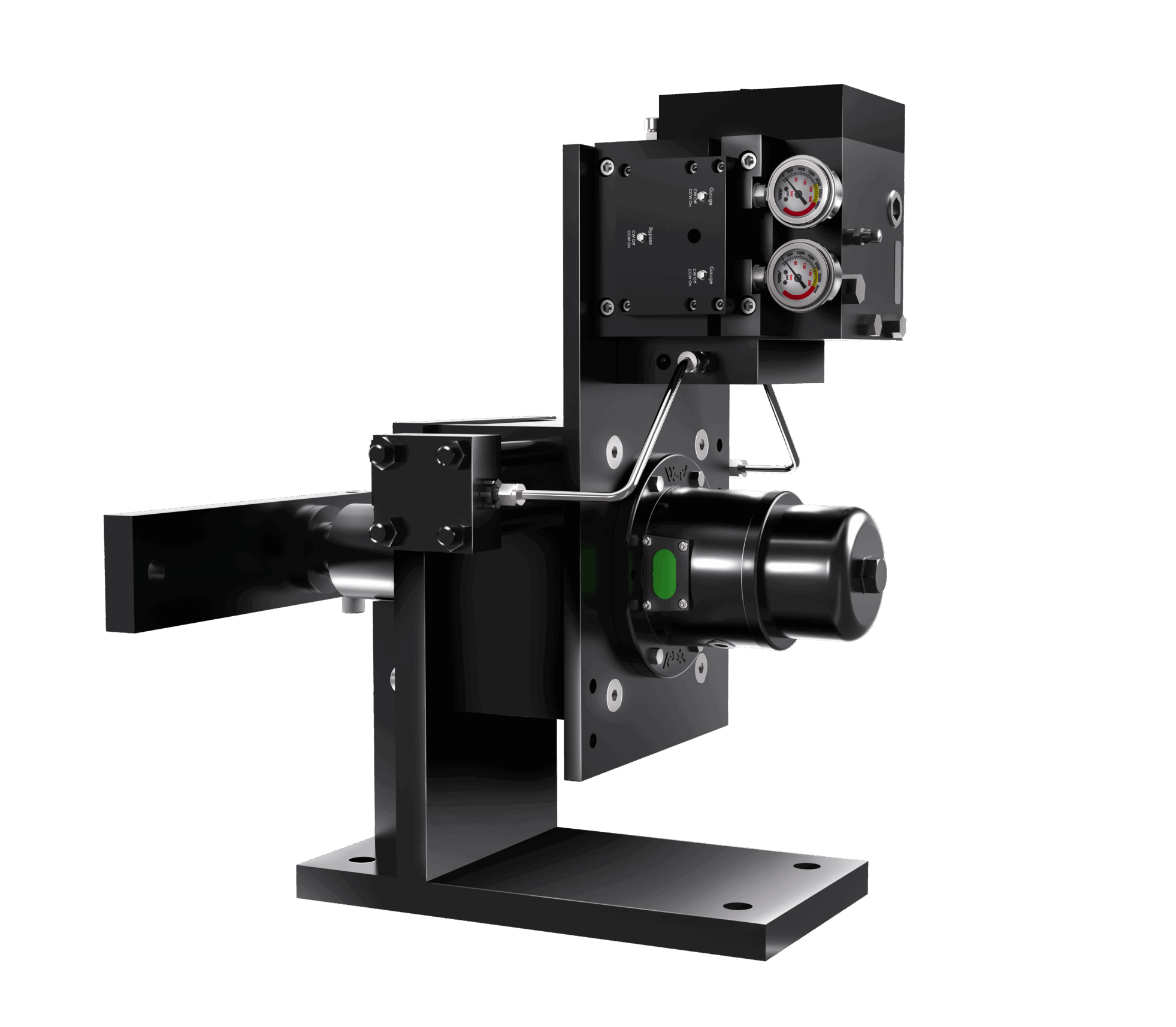

The system is comprised of an actuator assembly and the electrical control enclosure. The actuator assembly consists of a double acting hydraulic cylinder, position feedback sensor and an Electraulic™ Power Module. The power module is a unique, self-contained, sealed hydraulic pumping system which manages oil pressure and flow to and from the cylinder. The electrical control enclosure consists of the power supplies, motor drivers and a dedicated microprocessor. The combination of these mechanical, hydraulic and electronic technologies gives the XPAC Series 3 state of the art capability. All REXA products are proudly designed and manufactured in the USA.

How It Works?

The electrical control enclosure converts the incoming control signal into a target position and compares it to the current position of the feedback sensor. If the target position and current position deviation exceeds the user-programmed deadband, the microprocessor will initiate motion to adjust actuator position. A bidirectional gear pump, driven by an electric motor, generates the hydraulic output necessary to move the actuator. Oil travels from the pump through a series of pilot operated check valves, known as the Flow Matching Valves (FMV). Each FMV manages oil transfer out of one side of the cylinder and into the other. This builds pressure and drives the actuator to the target position. Once the target position is reached the motor and pump stop, and each FMV close, hydraulically locking the actuator cylinder in place. The motor will only turn on again if the signal deviation exceeds the deadband and a position change is required.