Global Aftermarket Service & Support

Supporting our customers is top priority. Our aftermarket service & support team is highly trained and ready to deliver exceptional on-site service of your REXA actuators. From installation and commissioning to preventative maintenance, to troubleshooting and repair, REXA has you covered.

With our continuously evolving technology, REXA aftermarket upgrade packages significantly optimize your equipment, integration with other plant systems and overall process performance. In addition, our hands-on training curriculum provides your technicians with a better understanding of REXA Electraulic™ Actuation. Learn more about our aftermarket services and our certified global representatives below.

Commissioning

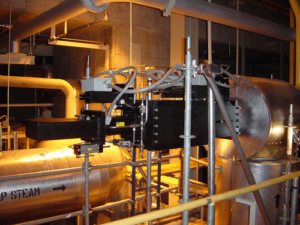

Our commissioning process consists of a set of engineering techniques and procedures to check, inspect and test every operational component of the actuator. Commissioning begins with a general inspection ensuring the alignment of the mounted actuator, tightness of fasteners, a mounted electrical enclosure, installation of the drive linkage, etc. Next, we conduct calibration and functional checks of input/output in accordance with design objectives and specifications. Customers can choose either just Dry Commissioning or both Dry and Wet Commissioning. Wet Commissioning is completely optional, but includes additional verification for calibration, operation and compatibility with other control elements.

Contact us today to learn more!