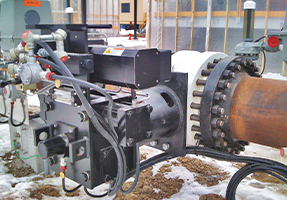

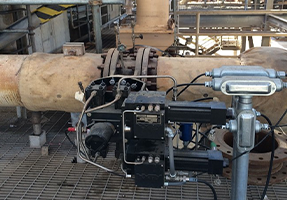

REXA Damper Drives can be configured to utilize a rack and pinion hydraulic cylinder or a double acting linear cylinder driven by one or more Electraulic™ Power Modules. Either configuration may be chosen to suit an application’s specific installation requirements. Our damper drives are commonly used on fan and stack dampers, burner tilts and other combustion control applications. REXA manufactures drive base and drive arm or mid/end pivot arrangement to suit any installation scenario.

- Simple, user-friendly push-button calibration

- Wide range of torques and thrusts are available

- Designed for harsh outdoor environments: NEMA 4X, IP66 rated

- CSA, IEC & ATEX certification available

- Fail-safe capable

- Low power consumption

Standard Features

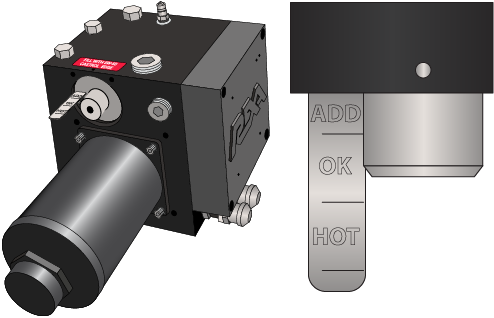

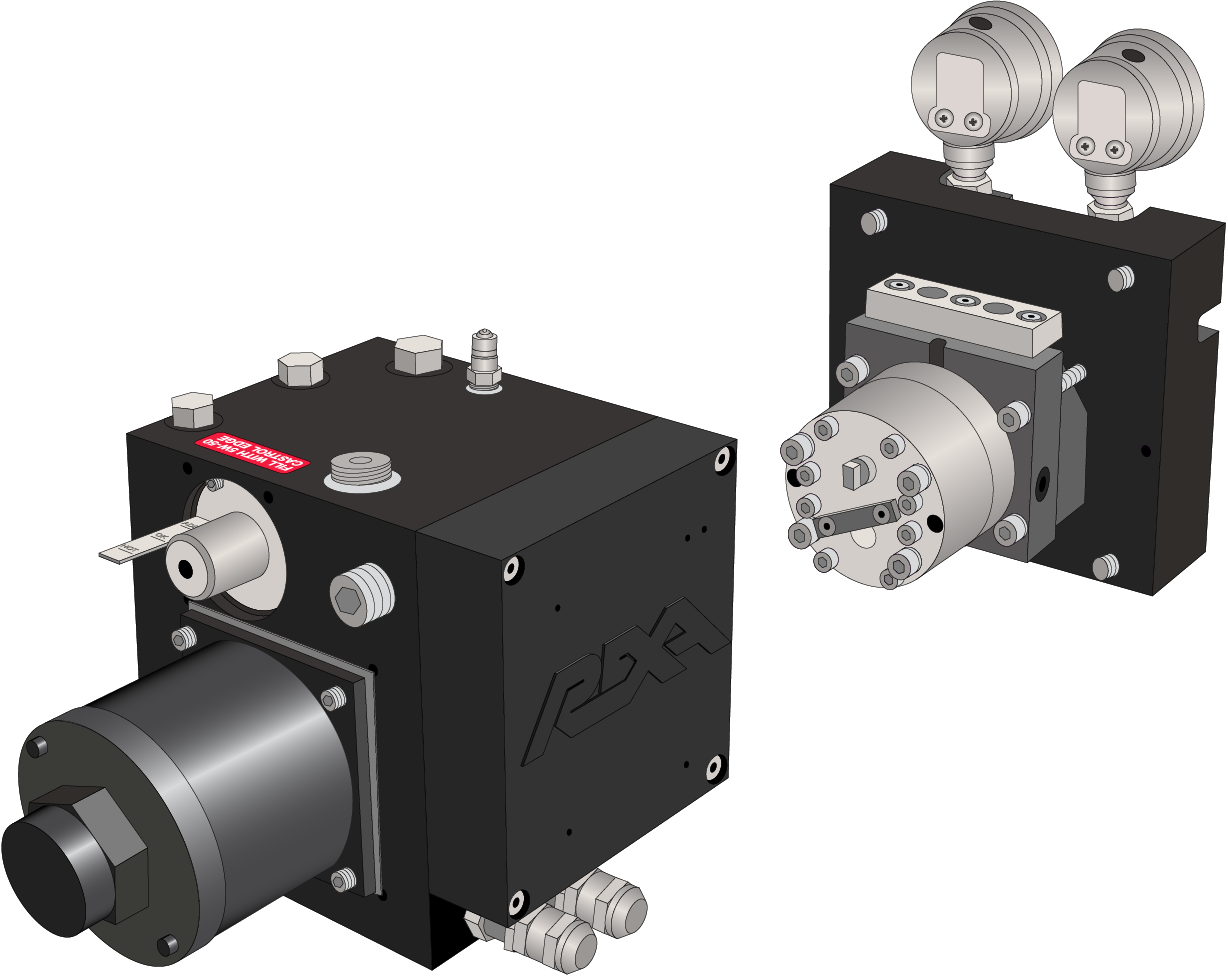

Electraulic™ Power Module

The key components of the Power Module include a 100% duty cycle motor, bi-directional gear pump, and Flow Matching Valves. This simple and compact design features a closed-loop, positive pressure hydraulic system which eliminates the need for active reservoirs and filters.

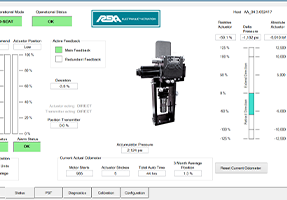

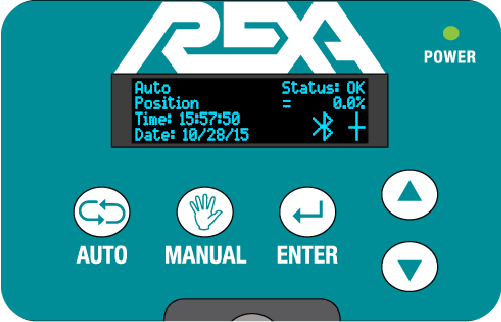

Display and Keypad

Simple, user-friendly push-button calibration. Displays mode of operation, current position, diagnostic warnings, and diagnostic alarms. A real-time clock provides event time and date stamping.

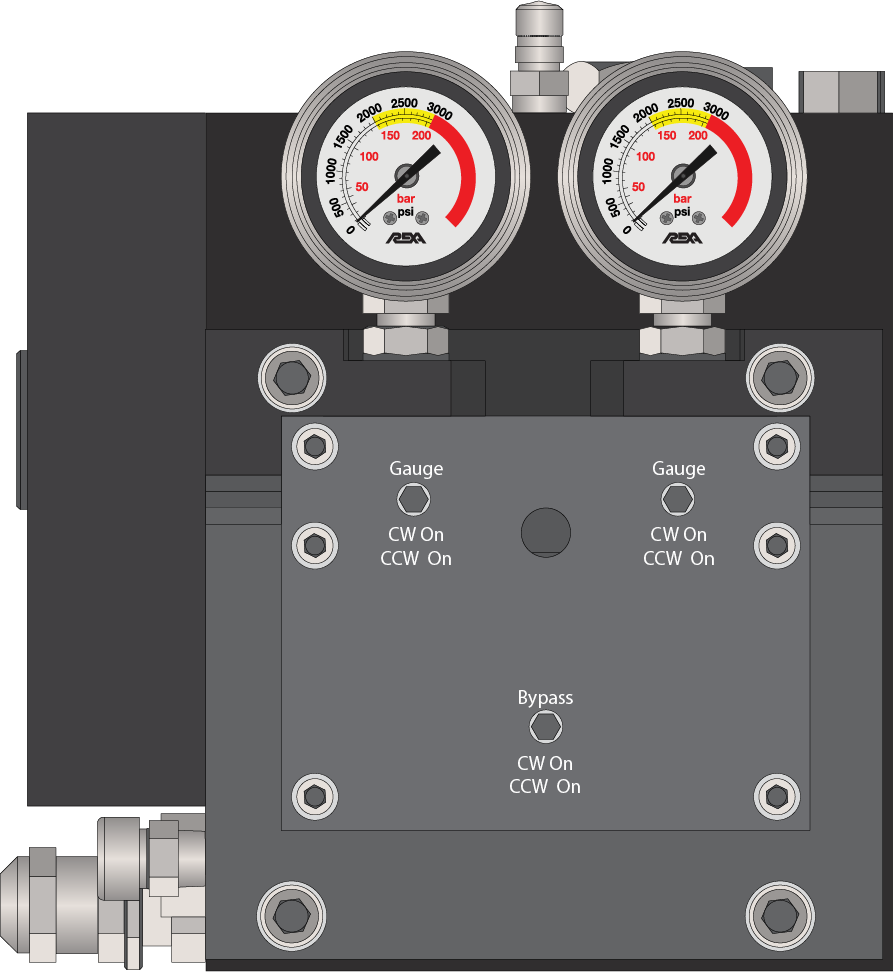

Pressure Gauges

Provided as standard equipment, these color-coded pressure gauges are helpful with troubleshooting should a problem arise. The gauges connect to a manifold with internal valves which isolate the gauges during normal operation ensuring high reliability.

Manual Bypass

An integral bypass is provided to equalize pressure on each side of the cylinder for use during installation and certain maintenance procedures.

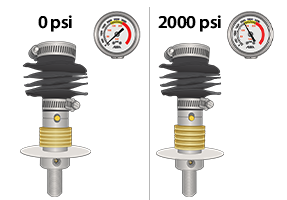

Oil Level Indicator

The expansion chamber includes a large spring loaded volume indicator. Stainless steel material and an environmental seal ensure smooth operation. A “dip stick” style gauge eliminates guess work to ensure proper oil levels.