Steel production is vital to many industries around the world. Some industries include general construction, machinery manufacturing, automotive, marine, and transportation. The world needs large volumes of high-quality steel to sustain the high demand. This is especially true during times of economic growth.

The blast furnace is a key component of many integrated steel mills. A chemical reduction process occurs within the blast furnace. Carbon dioxide converts iron oxides into “pig iron,” an elemental iron with carbon and sulfur containing impurities. Pig iron undergoes additional processing to make a variety of commercial steel products.

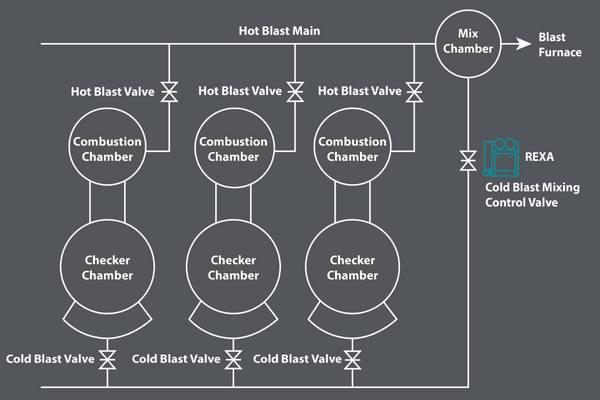

In Indonesia, a tier one steel producer uses REXA actuators in multiple applications, for the blast furnace. One application is positioning the cold blast mixing valve. This valve’s purpose is to blend cold blast air with hot blast main air, so the feed air temperature is constant. Constant air volume and temperature enables the reactions in the blast furnace to occur in a controlled manner. The outcome is a reliable blast furnace production of pig iron. A simplified process diagram is illustrated in Figure 1.

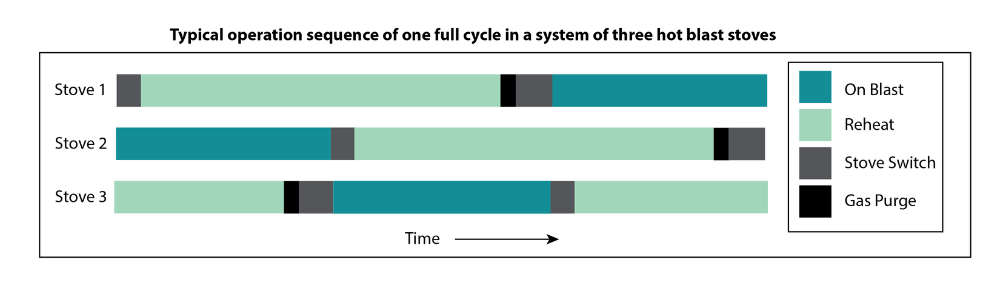

Two or three stoves are used to preheat the air to

around 1200°C (2190°F). The stoves are cylindrical steel structures lined with insulation and filled with checker brick. This is where the heat is stored and then transferred to the cold blast air. Air blowers feed 200°C (392°F) air to the ovens. The ovens cycle between preheating the air and being in reheat mode. Air entering a preheated oven exits at higher temperatures that dissipate over time until the next heated oven is utilized. The complex sequencing of the three stoves, switching modes, is illustrated in Figure 2. The actuator needs to position the mixing valve, without delay, so the mixed air has a constant temperature.

For seven years, the iron making section used pneumatic actuators to operate their mixing valves. These actuators were part of the original plant equipment scope. While pneumatic actuators are inexpensive and can control 1-2% of span, they have limitations in accuracy and reliability. The pneumatic actuators are associated with many issues including piston sticking, poor accuracy, and slow response time. The operations group upgraded to REXA actuators and are pleased with the results. REXA Electraulic™ Actuation delivers the position accuracy and reliability necessary to keep the blast furnace operating and producing high quality pig iron.

The REXA actuator and control panel, shown in Figure 3, are installed on a cold blast mixing valve. The REXA actuator is mounted on a 36-inch butterfly valve that is used to add cold blast air to the hot blast main mixer. The REXA actuator is capable of operating with 70mS deadtime and <0.15 positioning accuracy. This allows for reliable mixing valve positioning and ensures consistent blast air temperature.

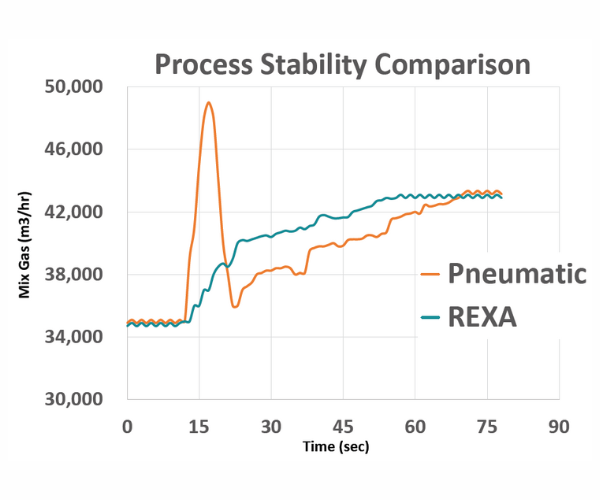

The Figure 4 graph shows the difference in gas flow with use of a pneumatic actuator versus a REXA actuator. The REXA has an advantage of fast and accurate valve movement without overshooting the control signal setpoint. The REXA actuator’s performance had really impressed the plant operations team. They decided to upgrade their blast furnace top gas damper actuators to

REXAs. They also plan to retrofit other actuators to improve the overall operational efficiency and reliability at the iron making section of the steel mill.

Download the full success story & learn more

Click the button below to download the full success story! Interested in learning more about our solution for other applications? Click here to further explore REXA in other applications.