West Bridgewater, MA, USA – REXA, the industry leader in electro-hydraulic actuation technology, announces its Electraulic™ Actuators are being installed by prominent oil and gas pipeline companies to maintain accurate metering of oil and petroleum products.

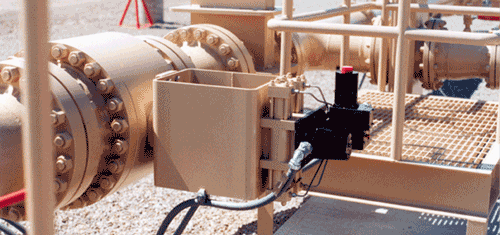

Meter runs typically consist of a flowmeter and a meter balance valve, for controlling the flow through the line, and a meter back pressure valve which the liquid flows through before entering the refinery, storage tank, or other points of use.

Accuracy in metering flow and in preventing a phase change during the flow through the meters is crucial in delivery and in determining product costs and pricing. The actuator controlling the valves must be able to provide quick response and precise control to maintain accurate flow rates through each meter run and avoid possible damage to a flowmeter. REXA’s Actuators have been tested time and again in the field to meet the requirements of precise and reliable actuator control.

Pipeline operators are finding that pneumatic, hydraulic, and electro-mechanical actuators provide less-than-satisfactory performance. The substitution of REXA Electraulic™ Technology provides the quick response and precise level of control required to maintain flow rates within the optimum accuracy range of flowmeters in the meter runs.

REXA Actuators are also used to create the back pressures essential for ensuring against phase changes and the possibility of cavitation. With valve control provided by Electraulic actuators, companies are trusting that their crude oil and petroleum products are reaching customers without problems in pipeline flow and at accurately determined pricing.