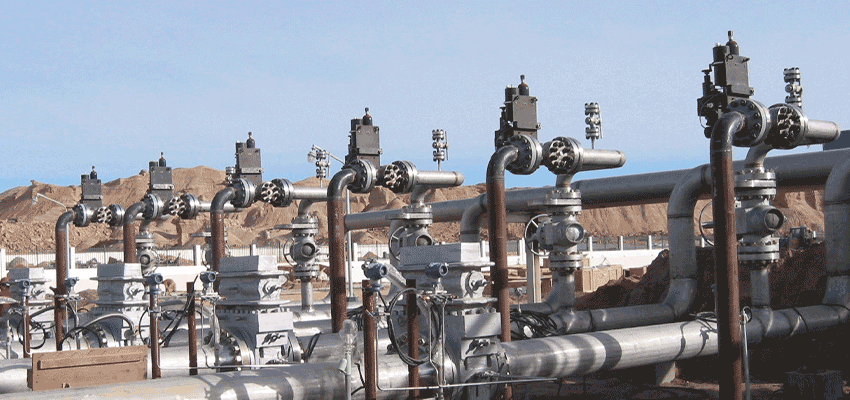

West Bridgewater, MA, USA – REXA, the industry leader in electro-hydraulic actuation technology, announces its Electraulic Actuators are being installed by leading oil and gas companies to protect from over-pressure conditions and provide stable delivery pressures

in their terminal systems.

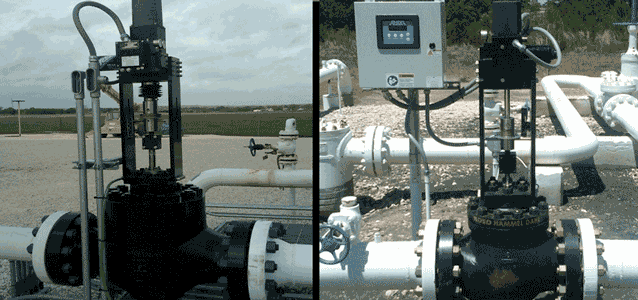

In the transfer of crude oil and petroleum products from the main pipelines to the terminals, control of the delivery pressure is critical. To accomplish this, terminal inlet pressure control valves are installed on delivery lines. The functionality of the valves is dependent upon their actuators. REXA’s actuators have been field-proven to offer the precise modulating control and ability

to respond rapidly to the normal pressure disturbances.

Pipeline companies have also found that REXA Electraulic Actuators have a fast response to commands and precise modulation of the terminal inlet pressure control valve. For instance, closure rates for 100% travel are between 10 and 15 seconds. By employing these actuators, pipeline companies have greater control of flow and can achieve stable pressures that are within the acceptable range for safe operation.

Unlike other actuator designs, REXA’s Electraulic Technology provides the quick response and precise control required to achieve stable pressure and ensure uniform delivery rates for a wide range of midstream transport applications.