Project Description

The filtration process removes suspended particles from water by passing the water through a medium. After a period of run-time, a filter needs to be “backwashed” to remove the captured particles from that run-period. Particle capture rate is important in ensuring filtered water contains no micro-organisms that could be harmful to people. Micro-organisms can be difficult to disinfect/remove from water, so operators measure the turbidity of water in order to gauge the capture rate of a filter. Ideally, an efficient filter runs the longest and captures the most particles (has the lowest turbidity).

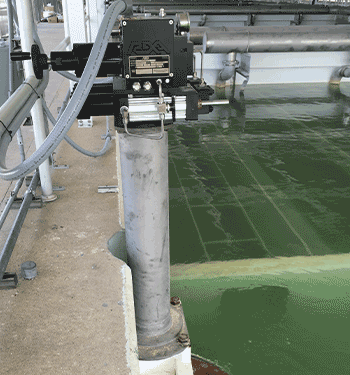

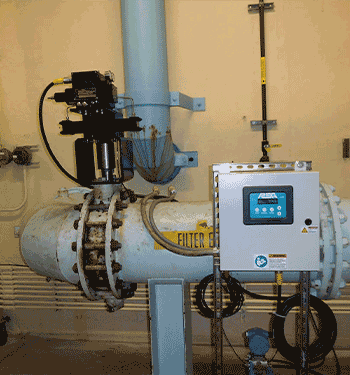

In a traditional gravity fed filtration system, the most critical valve application is the effluent control valve (commonly a butterfly valve). This valve typically sits at the bottom of the filter where it controls the rate of water flow moving through the filter. Commonly, accurate modulating control of filter flows with this valve is imperative to maintaining a constant, stable flow in a filter. The more stable the flow, the greater the capture rate. Surges in flow can occur when flow rates are not stable, which can allow suspended matter to pass through the filter – effectively increasing the turbidity of the filter effluent.

REXA Linear and Rotary Actuators have a history of success in the water treatment industry with controlling filter effluent valves. Maintenance-free operation of these modulating valves over decade-long periods is common. More importantly, the position accuracy of REXA Linear and Rotary Actuators (dead-band as tight as 0.05) can modulate a filter effluent butterfly valve disc in very finite increments that eliminate hunting. Precise position accuracy will stable flows through a filter, allowing for more efficient particle capture and lower turbidity.