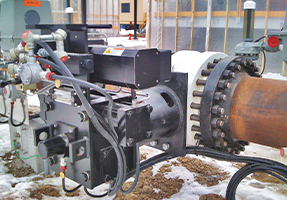

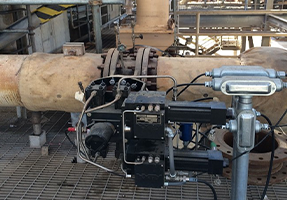

Project Description

What is Fail-Safe?

Fail-safe is a design feature that kicks in during system failure, therefore ensuring no harm to other equipment, people, or the environment. Critical process control applications often require the driven device to move to a fail-safe position upon loss of power or on a trip condition. Different applications call for either spring or accumulator positioning. Let’s dive into each one!

Spring

Spring fail-safe positioning involves a coil spring placed in series with the hydraulic cylinder. When a fail-safe condition initiates, an isolation solenoid opens the hydraulic circuit allowing the spring to move the driven device to the specified position. The condition initiates due to a loss of power, introduction/removal of a trip signal or a combination of both. Spring systems are simple, reliable and best suited for smaller sized actuators.

Accumulator

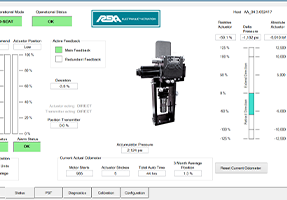

Accumulator fail-safe systems include a piston-type accumulator. During normal operation, a solenoid isolates the stored energy of the accumulator from the main hydraulic circuit. When a fail-safe condition is initiated, the solenoid opens to release the accumulator pressure, moving the driven device to the specified position. On the restoration of power, the Electraulic™ Power Module recharges the accumulator to a target pressure setpoint. Accumulator systems are an efficient use of stored energy. They have a compact power-to-size ratio for larger actuators and can also be configured to provide multiple strokes and/or rotations.

Check out our Fail-Safe videos below!

Want to Learn More?

Visit our Contact page to inquire about our spring and accumulator positioning capabilities for your critical process systems!