Project Description

Background

Furnaces help refineries and petrochemical plants break down and convert hydrocarbon fluids into fuels or chemicals such as gasoline, diesel, ethylene and propylene. As furnaces sometimes account for more than 50% of total plant energy consumption, small improvements in efficiency equate to large financial returns. Refineries and petrochemical plants tend to overlook draft control when making process improvements.

Optimizing the draft in a process heater is easy as there are many types of processes and instruments to choose from. The challenge is safely elevating process fluid temperature to a target level while maximizing thermal efficiency, throughput and reducing O2, CO and NOx emissions. Fast-acting, repeatable and accurate damper positioning enables fine-tuning of modern damper control systems.

Problem

Despite the high-level automatic control of instruments running complex loops in refineries and petrochemical plants, many dampers are controlled manually via cable and winch. This type of damper arrangement complicates accurate positioning, leading to poor furnace draft control. More importantly, manual operation of dampers creates a potential safety hazard to personnel – especially during emergency situations.

In an inexpensive attempt to automate a damper, a lot of plants select pneumatically-operated drives. Prone to hysteresis, static friction (stiction), overshoot and instability, pneumatic actuators face increased difficulty making small and controlled position changes. This inability to achieve stiff control limits the combustion process efficiency.

Solution

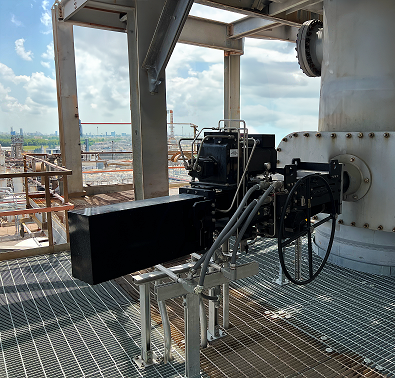

Upgrading or automating existing dampers with REXA Electraulic™ damper drives provides immediate benefits – enhancing furnace draft control. Learn more in our full Application Spotlight below!