West Bridgewater, MA, USA – REXA, the industry leader in electro-hydraulic actuation technology, announces its Electraulic Actuators have played a crucial role in the recovery of copper content at a mine near Tucson, Arizona, increasing capture by as much as 33,000 pounds annually.

At a copper mine near Tucson, Arizona, the concentrator can process up to 100,000 tons of sulfide ore a day. The mine had previously relied on pneumatic actuators to control the pulp height in its flotation cells via modulating dart valves. These actuators lacked precision due to the compressibility of air. In monitoring the slurry discharge copper grade, as well as occurrences of pulp surging over the launder lip, the mine operators found the results to be increasingly disappointing.

Ultimately, at least part of the problem was traced to the inability of the pneumatic actuators to control and maintain the proper pulp level in the tanks by effectively and rapidly opening and closing the dart valves in the tanks

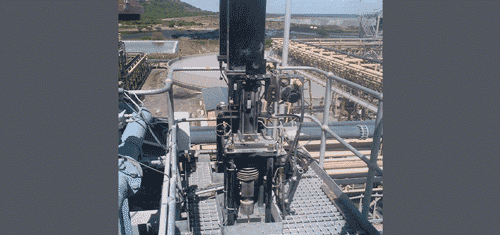

Improved control of the flotation level and the consistency were necessary. The flotation level needed to be controlled by actuators that provided precise modulation in opening and closing the valves in the tanks (two per tank). The pneumatic actuators were replaced with REXA Electraulic Actuators.

When installed in only two scavenger flotation cells, the four REXA actuators resulted in an immediate improvement in valve control, which has led to increased recovery of copper content during production runs. In fact, results during a test period after installation of REXA actuators indicated a 25% increase in the capture of the copper content in the scavenger cells during tank flow disruption.

REXA’s unique Electraulic™ Technology offers unmatched accuracy, repeatability, and reliability, allowing plant engineers to optimize control of pressures, temperatures, air flow, and other key process loops that measurably improve their operations.