Why Choose REXA for Downstream Applications?

Refineries and petrochemical plants focus on process up-time, unit availability and plant safety to achieve their goals. When considering the actuation needs in downstream applications, quick response, accurate positioning and repeatable control are critical. Luckily, REXA Electraulic™ Actuation is the perfect choice to meet those strict requirements.

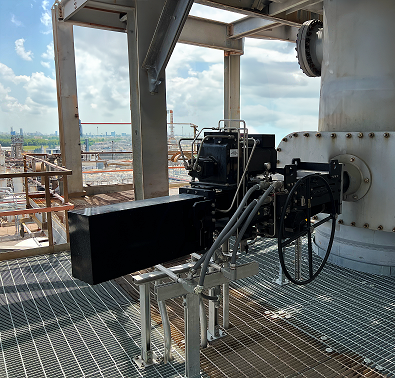

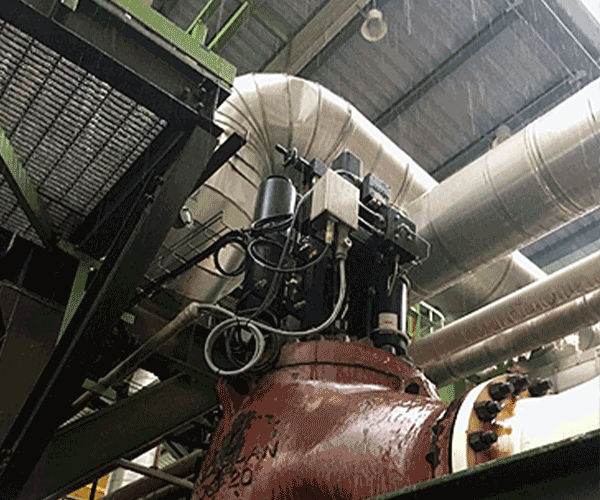

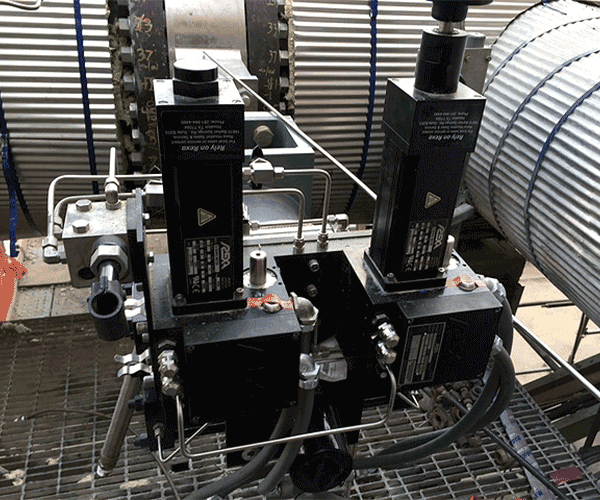

Our actuators provide the power, speed and performance of hydraulics without routine oil maintenance. REXA actuators are a closed-loop, positive pressure, sealed design and do not require an external reservoir or oil filtration system. This unique and inherently clean approach to hydraulics provides years of trouble-free operation, avoids unplanned shutdowns and maximizes plant throughput.

- Accurate and repeatable positioning

- Immediate signal response (<70ms deadtime)

- 100% modulating duty cycle

- Large thrust & torque outputs

- Fail-safe capable (spring or accumulator)

- REXA customizes adaption hardware to fit any valve, damper or turbomachinery application.

More and more plant operators are choosing to rely on REXA for their most challenging applications. Check out the featured applications below to learn more!

Check out our featured Downstream Applications

- Furnace and Heater Stack DampersNick Lalos2020-03-03T11:33:12-05:00

Furnace and Heater Stack Dampers