Project Description

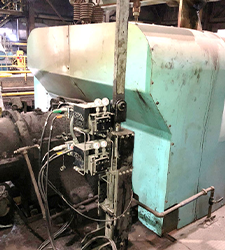

The coking process takes place over a span of 12-36 hours in a coke oven. Once pushed out of the vessel, the hot coke is often quenched with water to cool it before storage. After the coke has been cooled, it is transferred to the blast furnace for use in iron making. REXA Linear and Rotary Actuators are used to effectively deliver quenching water to cool the coke by controlling the header pressure.

Benefits:

- Precise modulating control

- Reliability