Project Description

In transporting crude oil and pipeline petroleum products to refineries, storage tanks, and other delivery points, metering of the fluid is essential for determining flow rate, volume, and ultimately, cost. In situations where the flow in the input line may vary significantly, multiple meter runs are required in order to maintain flow rates within the optimum accuracy range of each flowmeter. Such meter runs branch off of a manifold and run in parallel, dividing the flow among the individual runs.

Meter runs typically consist of the flowmeters and a Meter Balance Valve, which enables control of the flow through the line to ensure that it is within the effective accuracy range of the meter and that it is consistent with the flow through the other meter runs.

In Meter Balance Valve applications, ball valves are generally preferred, although globe valves and butterfly valves may be used. Ball valves provide good control characteristics with wide rangeability at moderate costs. Globe valves offer the advantage of better throttling control, while butterfly valves are a lower cost solution, but with reduced control performance. Whatever the type of valve, the actuator controlling the valve must be able to provide quick response and precise control to maintain accurate flow rates through each meter run and avoid possible damage to a flowmeter.

The flows from the individual meter runs are combined, and the liquid flows through a Meter Back Pressure Valve before the petroleum enters the refinery or storage tank. The purpose of the Meter Back Pressure Valve is to maintain sufficient back pressure on the flowmeters to ensure there is no phase change as the product flows through the meter.

Any amount of phase change can affect the accuracy of the meter. The valve, controlled by an actuator, must provide fast response to main line pressure changes, as well as flow and pressure changes in the delivery line.

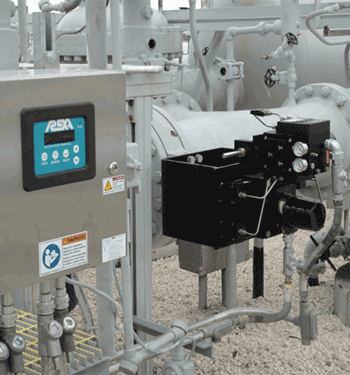

REXA’s Electraulic Actuation™ provides the quick response and precise level of control required to maintain flow rates within the optimum accuracy range of flowmeters in the meter runs. REXA Actuators are also used to create the back pressures essential for ensuring against phase changes and the possibility of cavitation.

Benefits:

- Ideal for strict environmental requirements

- Fail-safe capability and surge control options

- CSA Division 1 and 2 approvals

- Wide ambient temperature ranges

- Efficient power consumption

- No oil maintenance