Project Description

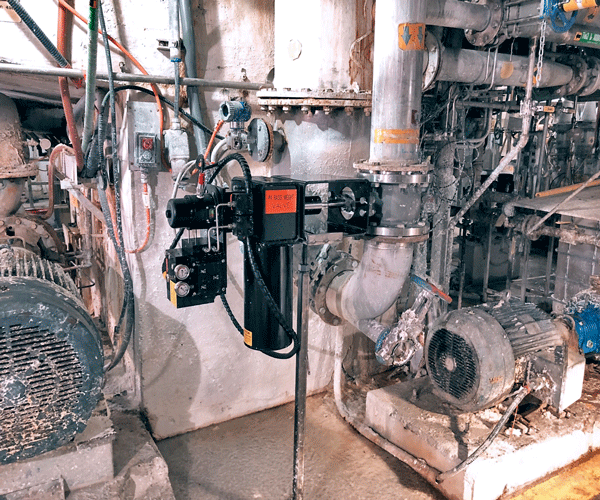

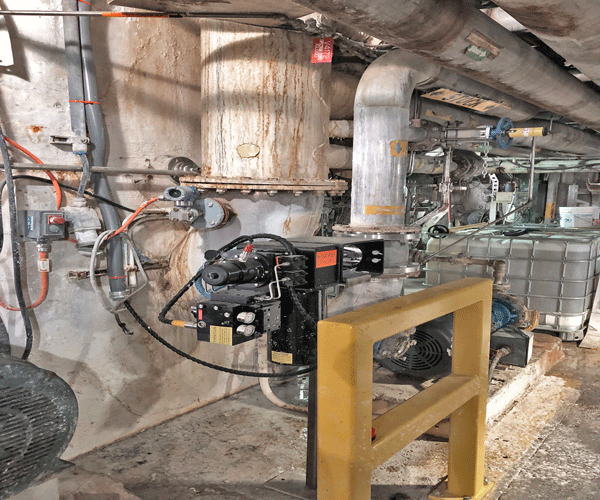

REXA installed an Electraulic™ Actuator on a basis weight valve at a paper mill in the Northeast United States. We performed an extensive benchmark test to verify the REXA basis weight solution meets or exceeds the performance of the existing actuator. After eight months of run time, we collected process data to verify actuator performance.

What is a Basis Weight Valve?

The basis weight valve is the most critical component on the wet end of a paper machine producing fine paper. This valve modulates the flow of stock as it is mixed with white water on its way to the head box, as well as forming wire where the sheet begins to take shape.

What’s the Key to a Successful Process?

Paper making is a complex process involving a variety of operations. From wood preparation, to pulping, to bleaching, to the paper machine, many variables affect the finished product. In addition, the type of wood available and the type of paper produced significantly affect each paper mill’s operation.

Each paper machine is designed for a specific basis weight range and roll speed. Therefore, reliably producing quality paper requires precise control of the basis weight valve. Fluctuations in the basis weight result in uneven drying, a poorly finished product and/or waste. Consequently, this leads to a rejection of the whole roll. Mills need a high-performing, reliable, responsive actuator capable of making fine position changes without overshoot while maintaining this performance level at a high duty cycle.

Solution

Check out our full Application Spotlight below to learn more about the mill’s application and see how REXA provided the best-fit solution!

Is Your SKF Basis Weight Actuator No Longer Supported?

Download our flyer below to learn how you can easily replace your SKF actuator with a REXA Electraulic™ actuator!