Project Description

Background

Increased regulatory pressures to reduce emissions along with a declining generation demand create challenges for a plant’s operating practices. Plant operators are forced to adopt new practices and advanced technologies to improve efficiency and increase reliability.

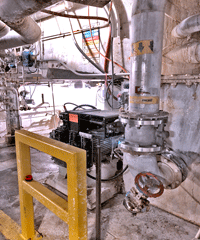

Within a furnace draft pressure control application, Primary Air (PA) fans deliver the required fuel from the pulverizers to the furnace to meet generation demand. Force draft (FD) and Induced Draft (ID) fans control air and combustion gas flow through the boiler.

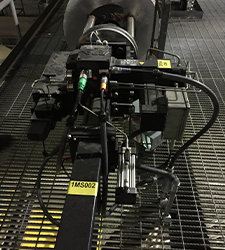

The precise control required to maintain furnace draft can be a difficult proposition – particularly for plants that are cycling. Inadequate FD/ID damper operation negatively affects performance of low NOx burners, while poor damper performance and inadequate pulverization leads to increased fly ash.

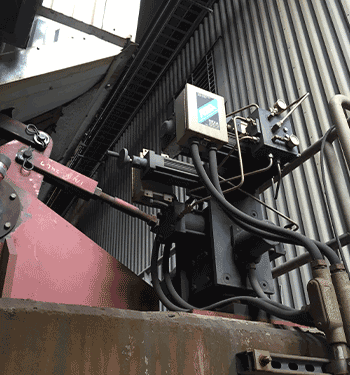

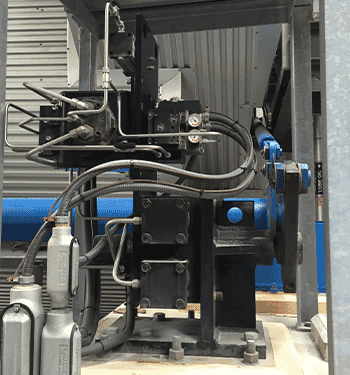

REXA actuators offer a rugged, repeatable and responsive solution for combustion optimization and accurate furnace draft pressure control. Check out the full Application Spotlight below to learn more!