Project Description

Background

A Net Positive Suction Head (NPSH) is available for a boiler feedpump, specific to the design and piping layout of every plant. This defines the inlet pressure at the suction side of the pump, due to the effects of gravity and system design. If the pump draw exceeds the NPSH, the inlet line pressure would drop below the vapor pressure, therefore resulting in flashing and cavitation. Not only would the cavitating feedwater physically damage the pump, the reduced flow rate would allow the pump to overheat.

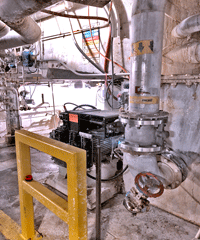

To prevent this, a minimum available flow must be maintained to circulate through the pump, regardless of downstream boiler load requirements. To protect the boiler feedpump from damaging conditions, plants have a recirculation line bypassing the boiler and recirculating feedwater directly back to the deaerator or condenser. This recirculation line ensures that the boiler feedpump has the required flow available to protect the pump at all boiler load conditions.

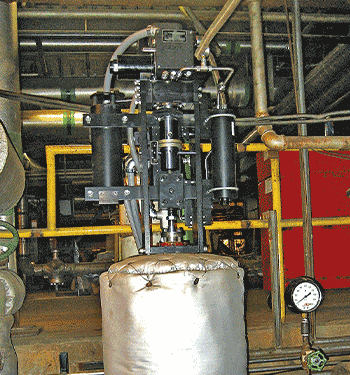

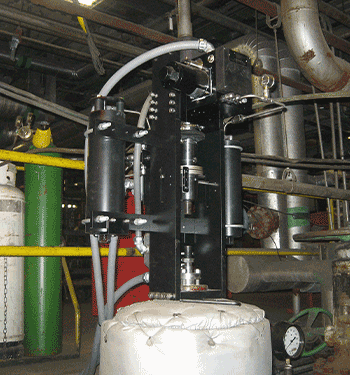

Responsive and repeatable control of the Boiler Feedwater Recirculation (BFR) Valve protects a plant’s investment in the boiler feedpump while allowing it to deliver the required flow to the boiler. The feedwater recirculation valve is responsible for taking almost a full pressure drop across the valve. This valve is typically designed for Class V shutoff and to fail-open on loss of power since it is usually closed during normal operations.

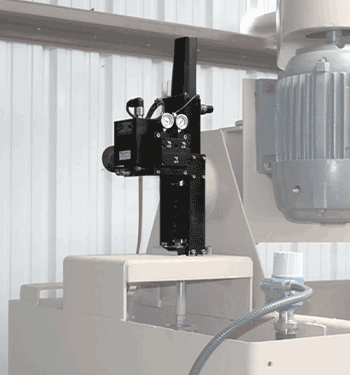

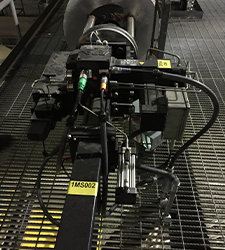

Most plants still utilize pneumatic spring and diaphragm actuators for their BFR valves. Unfortunately, pneumatic actuators lack the necessary rigidity to accurately control small steps. REXA actuators, however, offer repeatable, stiff, and accurate valve control performance – allowing for tight shut-off.

Read more in-depth about Boiler Feedwater Recirculation Valves in our Application Spotlight below!