Project Description

Background

Attemperators have been a key component of Combined Cycle Power Plants for many years. Back when these units were base-loaded, spray water control wasn’t an issue. In today’s world, however, plants are ramping up and down daily – consequently putting a strain on steam temperature control regulation. Controlling superheat temperature enables plants to maximize efficiencies and improve heat rate.

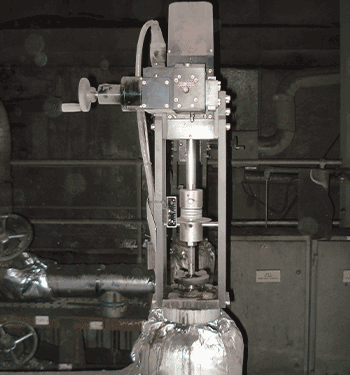

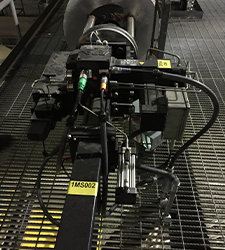

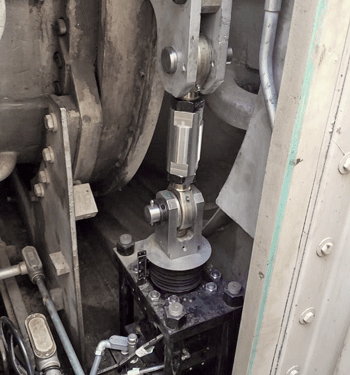

Depending on their type and design, each plant uses multiple strategies across various systems to accurately control temperature. Almost all use superheat spray valves as the “final” control of steam temperature entering the turbine. Since plants need to cycle to lower loads more frequently, many now use feed-forward, cascade and adaptive-predictive control strategies which result in tighter control of superheat steam temperatures. With the wrong actuator operating the superheat spray valves, numerous issues can arise.

REXA Linear and Rotary actuators are key components in helping plants achieve their efficiency goals by maximizing performance through tighter resolution, stiff repeatable positioning and high duty cycle operation. Learn more in the full Application Spotlight below!