Project Description

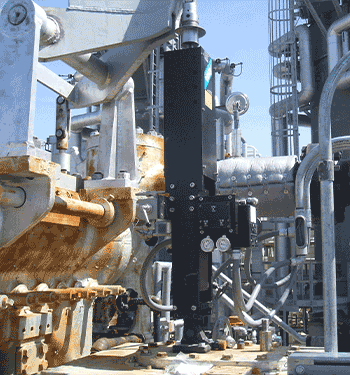

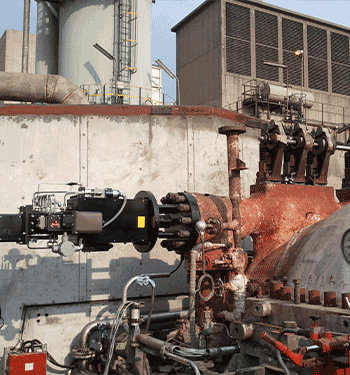

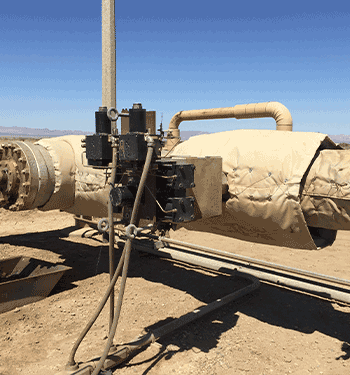

Steam Turbines are used in utility and industrial power accounts to generate electricity. The steam turbine is directly coupled to the generator in this application. The steam turbine governor controls the flow of steam into the turbine casing to maintain the turbine rotor speed of rotation at a constant value. The governor may be controlling a number of control valves, or a number of control nozzles that are staged in operation by a camshaft or bar assembly. A hydraulic cylinder, powered by the lube oil system or by an electrohydraulic control oil (EHC) system, utilizing servo or proportional valves, is typically the motive force for operating the governor valve. Accurate and repeatable speed control is essential in this application to synchronize frequency with the electric power system.

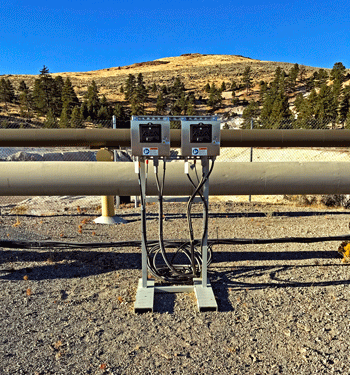

Traditional HPU based hydraulics are compromised by degradation of oil cleanliness over time, requiring these systems to have a high maintenance level. REXA’s self-contained design eliminates the need for HPU based servo/proportional systems that are maintenance intensive. REXA Actuators require no filters, and absolutely no oil based preventative maintenance, making them highly reliable. Maintenance intervals for REXA Actuators on steam turbine governors are not typically required until after 7-10 years in service. REXA’s high performance allows for control at +/- 1 RPM, allowing for fast synchronization and premium load control.