Project Description

Coke ovens process coal into coke that is used as a fuel source in blast furnaces. Coke ovens run continuously and do not use air as a combustion source. The co-product gas exiting the coke oven is tightly pressure controlled to +/- 1 millibar. Excess pressure may cause the gas

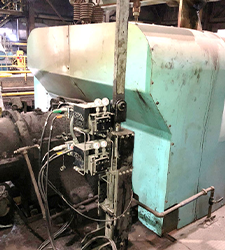

to be diverted from the co-product plant to atmosphere. Insufficient pressure may cause air to enter the oven, ruining the coke. REXA Linear and Rotary Actuator’s 100% duty cycle capability is used to precisely control the coke oven collection line gas pressure.

Benefits:

- Precise Modulating Control

- Reliability

- 90 degree normal, 355 degree maintenance rotation