Project Description

Background

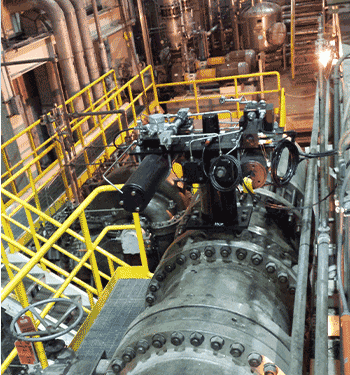

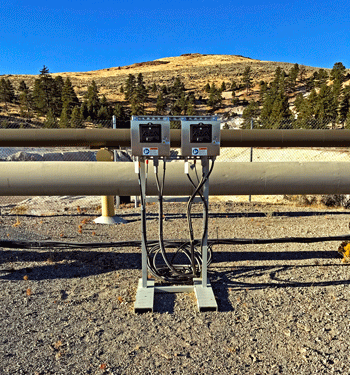

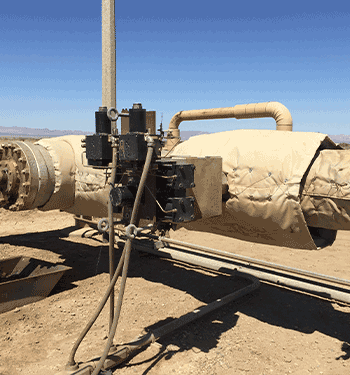

The condenser is a key component in any power plant that uses a steam turbine. Its primary function is to increase power by maximizing the pressure drop across the turbine, where efficiency is directly related to the vacuum created by condensing steam. Geothermal condensers are fundamentally different than those found in fossil fuel plants, in that turbine exhaust steam is never recycled to a boiler. Therefore, a direct contact condenser is typically used. In lieu of cooling tower water run through sealed piping, it’s sprayed into the steam, and drains to the condenser hotwell. From there it’s pumped through the level control valve and into the cooling tower, cooled, and collected in the cold-water basin at the bottom of the tower. It is then fed back into the condenser, for the process to repeat. Regardless of plant design, maintaining a proper condenser hotwell level during all phases of operation is critical to generate rated megawatt output.

Learn More

Check out our Application Spotlight and Video highlighting how upgrading to REXA Electraulic™ Actuators enables increased hotwell level control!