Project Description

Background on Inlet Guide Vanes

Inlet Guide Vanes (IGVs) deliver air to the inlet of a gas turbine’s axial compressor. While maintaining proper fuel-to-air ratio through various load ranges, they minimize the potential for unwanted emissions. In present-day Combined Cycle power plants, IGVs ultimately control the exhaust gas temperature – a critical input to the Heat Recovery Steam Generator (HRSG). Stable control of the exhaust gas temperature enhances the combined unit’s level of efficiency.

Many current day turbines use low NOx combustors that require a lean air-fuel mixture. As hot gas temperatures decrease, the formation of NOx also decreases. With a higher air mix, it’s critical to control the exact amount of air into the combustors – especially during low loads.

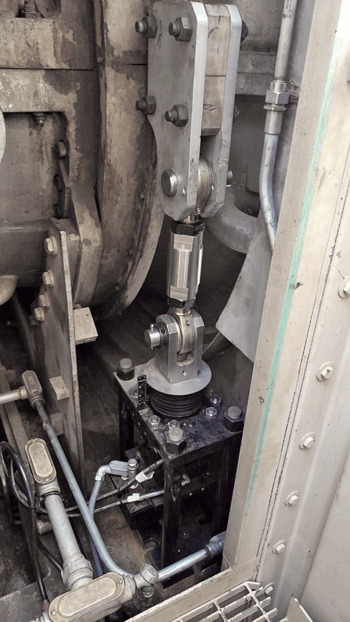

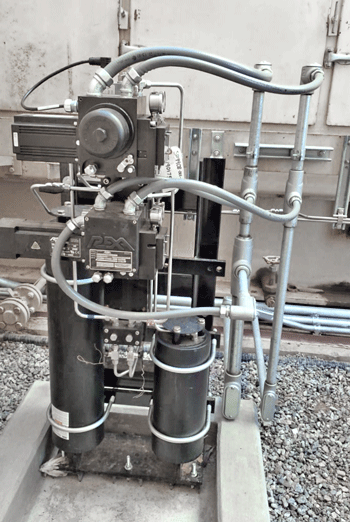

The REXA Solution

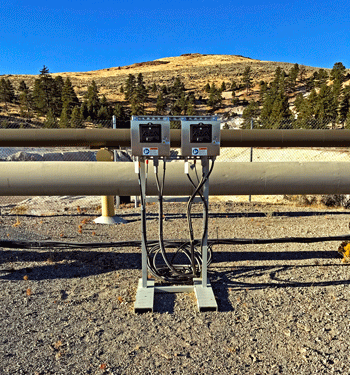

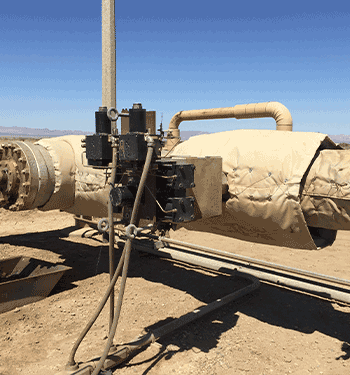

REXA’s Electraulic™ Actuators provide responsive, repeatable control for IGV applications on all major manufacturers’ combustion turbines. Designed for continuous modulating service, the patented self-contained and closed-loop hydraulic circuit within our actuators provides stiff and stable control in the harshest environments. This system does not need any filters or oil-based maintenance.

A membrane key pad on the enclosure cover ensures simple set-up and calibration. Actuator performance is unmatched within the industry with adjustable dead-band to 0.05% of stroke, resolution of <0.1% and frequency response of 1.5 to 5.0 Hz.

Learn more in our full Application Spotlight below!