Project Description

Background

Reheat Attemperators are used as a final control element of steam temperature into the IP section (sometimes LP section depending on plant design) of the Steam Turbine. The steam extracted from the HP section of the turbine is passed back through the boiler and reheater prior to entering the next stage of the turbine.

These attemperators spray water into the reheat line to control the steam temperature. Like superheat attemperators, reheat attemperators are subject to the changes made in controlling flue gas temperature in combustion. However, the reheat steam pressures exiting the HP are much less than superheat steam pressures entering them – meaning the pressure drop across reheat temperature control valves is much greater. This dynamic can create cavitating process conditions creating rapid and excessive trim wear in these valves.

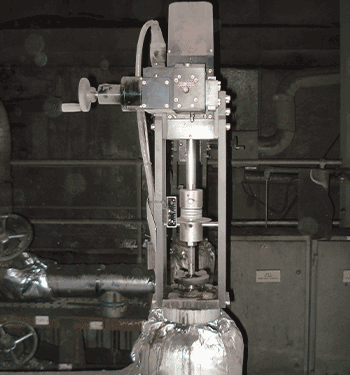

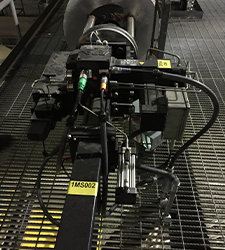

Using REXA Linear and Rotary actuators in reheat temperature control applications increases cycling power plants’ efficiency allowing for minimal valve throttling capabilities, tight shutoff and maximum trim life. Learn more in the full Application Spotlight below!