YouTube Series: Electraulic™ Actuation Overview

You may be familiar with various actuation technologies like electric, hydraulic and pneumatic, but how about Electraulic™? Unique to REXA, this brand of actuator combines the benefits of the above actuation technologies while eliminating drawbacks typically associated with each.

Electraulic™ Actuation consists of two major components: the mechanical sub-assembly and electrical sub-assembly. Its foundation is in the breakthrough hydraulic circuitry technology called the Flow Matching Valve System. In conjunction with a bi-directional gear pump coupled to either a DC stepper or AC servo motor, this system is a highly efficient method to move hydraulic fluid from one side of a double-acting cylinder to the other.

Learn more about what sets us apart from the rest in our Actuation Overview video! While you’re there, consider subscribing to our YouTube channel for similar content!

A REXA Success – Wellhead Valve Application

With about one-sixth of the carbon dioxide emitted by a clean natural gas-fueled plant, Geothermal energy production ensures a sharp reduction in greenhouse gas emissions. There are three types of Geothermal plant designs – dry steam, flash and binary cycles.

Regardless of plant design, everything begins at the Well Head. Often separated by significant distances, production wells include Emergency Shutoff Valves (ESVs) and flow control valves – both of which play key roles in the process. Therefore, they need to function reliably to ensure no interruption of the flow of steam or brine to the plant.

A Geothermal power plant in New Zealand recently experienced unstable control of their Production Wellhead valves and sought out REXA for the right solution. Click here to continue reading this success story and find out how we were able to help this plant achieve greater control of their Wellhead valves while reducing water hammer down the process line!

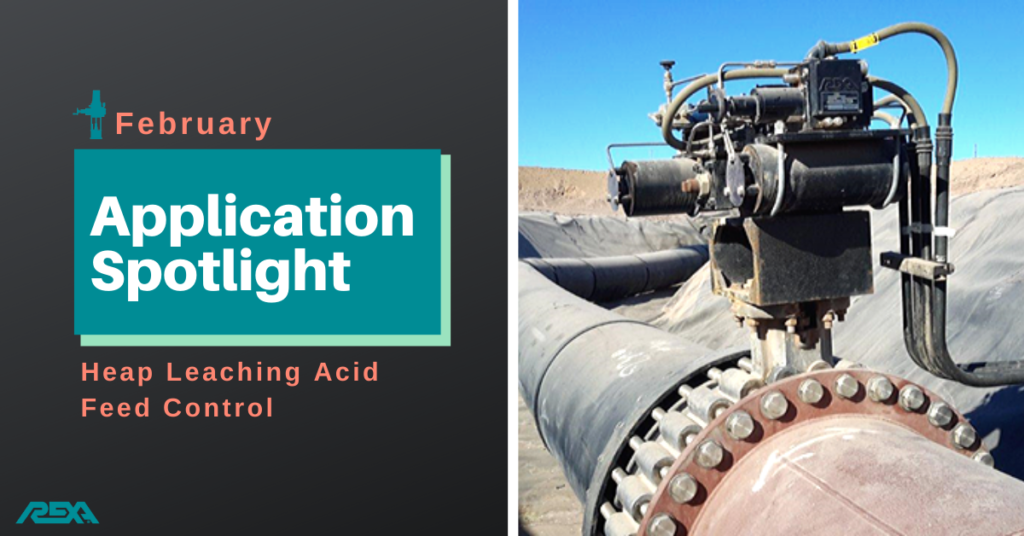

Application Spotlight – Heap Leaching Acid Feed Control

February’s Application Spotlight focuses on Heap Leaching Acid Feed Control – a critical process within the mining industry. Heap leaching consists of the extraction of precious metals from ore through a series of acidic chemical reactions. These chemical reactions absorb specific minerals and re-separate them.

Heap leach mining differs from in-situ mining with the use of a heap pad to separate the ore. The process begins by physically wetting and agitating the milled ore to form small spheres. It is then placed on a heap pad while diluted acid is added via a drip system. Upon completion of the leaching process, solvent extraction processes the pregnant leached solution to further purify the copper solution.

Minimal process variation of feed solutions entering the kiln is essential to produce high quality agglomerated ore. Typically, pneumatically-controlled globe or ball valves control the acid feed flow to the mixer. Unfortunately, these actuators cannot reliably control the valve to position due to the compressibility of air.

Click here to learn how we helped a mine in Arizona dramatically improve control performance!

REXA Around the World – Mexico

Join us each month as we travel the globe featuring various REXA installations! This month’s featured installation is on Turbine Bypass Valves at a Combined Cycle power plant in Mexico. These valves ensure proper operation of Turbine Bypass systems.

Improperly functioning turbine bypass system valves contribute to unscheduled downtime and trip events. Every unscheduled trip event adds to equivalent plant starts and greatly reduces the planned maintenance intervals as part of Long-Term Service Agreements (LTSAs) – therefore causing plants to spend millions before they need to.

Our Electraulic™ actuators eliminate these issues, optimizing transitions and preventing nuisance trips during ramp-up, ramp-down and emergency response scenarios. Designed for continuous modulating service, the actuators’ patented hydraulic circuit provides stiff and stable control in the harshest conditions (-40°F to +250°F). Adjustable deadband to 0.05% of stroke, resolution of <0.1% and full stroke speeds to 1 second equate to actuator performance unmatched in the industry.

Check out our full page dedicated to Turbine Bypass Systems here to learn more!